- - What is 3D Printed Dental Implant?

- - Why Choose Turkey for 3D Printed Dental Implant?

- - 3D Printed Dental Implants Images

- - Applications of 3D printing in dental implants in Turkey

- - Benefits of 3D Printed Dental Implants

- - Material used in 3D printed dental implants

- - The Importance of Biocompatibility for a 3D-Printed Dental Implant

- - Steps of the 3D-Printed Dental Implant Procedure

- - 3D Printed Dental Implants Limitations

- - Future of 3D-Printed Dental Implants in Turkey

- - 3D Printed Dental Implant vs. Traditional Implant

- - Get a Precise 3D Dental Implant with Turkey Luxury Clinics

3D-printed dental implants are revolutionizing tooth replacement by offering patient-specific customization, precise fit, and faster recovery times.

3D printing technology plays a crucial role in the manufacturing of dental implant prosthesis components such as crowns, bridges, and abutments.

By relying on precise digitalization of each patient’s anatomy, it ensures a perfect fit and seamless integration with dental implants. At Turkey Luxury Clinics, we offer this advanced technology to provide our patients with faster procedures, greater comfort, and long-lasting results

This guide explains how it works, benefits, and future potential of 3D printing in dental implants, offering a comprehensive look at how this technology is revolutionizing the dental industry.

What is 3D Printed Dental Implant?

3D printing is an advanced dental implant technology that allows the creation of custom-fit, patient-specific dental implants. This technology enables the manufacturing of implants guides and prosthesis with complex, personalized designs and features that enhance proper osseointegration (bone growth around the implant), leading to a more stable result and a more comfortable, painless and faster patient experience compared to traditional implants.

Why Choose Turkey for 3D Printed Dental Implant?

3D-printed dental implants has become a popular option for dental implants in Turkey, with many clinics utilize 3D imaging, computer-aided design (CAD), and 3D printing to create surgical guides, customize restorations, and streamline the entire process, from planning to placement to ensure proper fitness, precise efficacy and patient’s comfort.

Cost-Effective Packages:

- Many Turkish clinics offer competitive prices, often bundled with all inclusive dental implant packages.

- These can include consultations, medical procedures, imaging, and even non-medical expenses such as accommodation and travel.

- Premium packages may provide additional services, including post-operative follow-ups, required medications, longer stays in luxury hotels, and even guided tours—allowing patients to combine effective treatment with an enjoyable experience.

State-of-the-Art Clinics and Expertise with Digital Workflow:

- Turkish clinics feature advanced facilities, extensive experience, and high-quality care.

- Many are JCI-accredited, and the dental experts are internationally certified, with advanced training and foreign accreditations.

- Many clinics with In-House Digital Lab are adopting a fully digital workflow, integrating CAD/CAM technology and 3D printing throughout the entire process to enhance precision, efficiency, and patient outcomes.

Positive patients’ reviews and testimonials:

Patients consistently report high satisfaction with 3D-printed dental implants in Turkey, highlighting predictable outcomes, faster recovery, and long-lasting results. These positive experiences make Turkey a leading destination for dental tourism, offering world-class care combined with affordable treatment packages.

Read about: Best Dental Implant Clinics in Turkey & Best Dental Implant Surgeon in Turkey

3D Printed Dental Implants Images

Applications of 3D printing in dental implants in Turkey

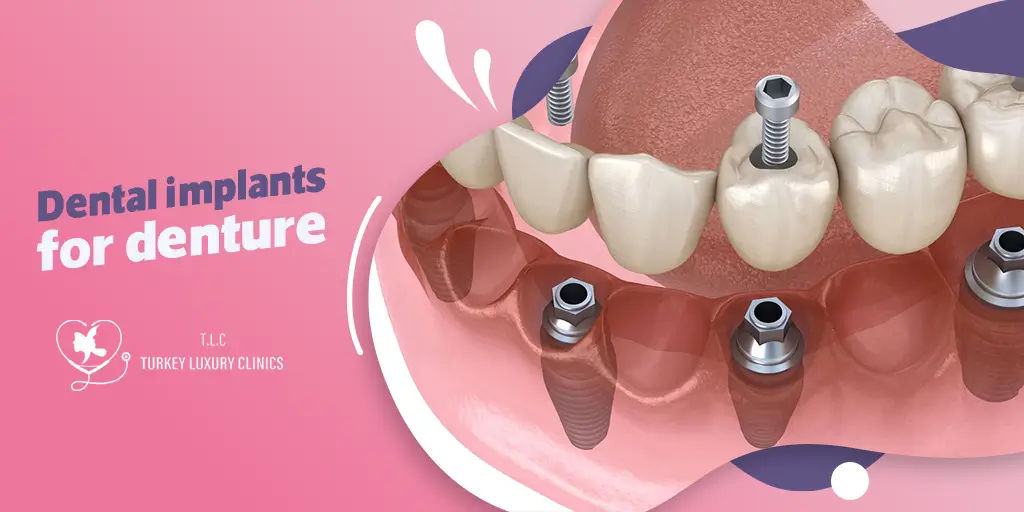

3D printing in dental implant dentistry is mainly applied to create patient-specific surgical planning models, customized components, and surgical guides. These applications make implant dental procedures more accurate, efficient, and comfortable for patients.

3D printing is also widely used in prosthesis fabrication, including crowns, bridges, abutments, and dentures, allowing them to be precisely printed in the desired size and shape. They can be made of either high-quality plastics or specialized metals.

The main uses of 3D printing in dental implants include:

1. Patient-customized abutments for better fit, stability, and improved function.

2. Patient-customized crowns for natural appearance and precise adaptation.

3. 3D-Printed dental implant surgical guides for accurate implant placement and reduced surgical errors.

4. Patient-customized bridges for optimal comfort and long-lasting results.

5. 3D Printed models for surgical planning for enhanced accuracy and predictable treatment outcomes.

Benefits of 3D Printed Dental Implants

Compared to traditional implants, 3D printing allows the creation of implants and prostheses tailored to each patient’s anatomy, increasing comfort and reducing discomfort. This provides several advantages over conventional implant methods:

- Accurate Fit: Digital scans and 3D printing ensure implants and prostheses fit perfectly. For implants, this allows better osseointegration, faster tissue healing, and successful integration. For crowns, an accurate fit improves comfort, longevity, and aesthetics.

- Faster Recovery: A precise fit promotes quicker osseointegration and tissue healing, enabling patients to enjoy their restored teeth sooner with less risk of implant failure.

- Shorter Procedure: 3D-printed implants allow smoother, more predictable tooth restoration, reducing the number of dental visits, shortening overall treatment time, and providing stable, long-lasting results.

- Better Patient Experience: Personalized 3D-printed implants feel more natural, increase comfort, and reduce pain due to optimal mouth and tissue fit.

- Cost-Effectiveness: 3D printing can lower production costs and reduce material waste, making implants potentially more affordable than traditional methods.

Material used in 3D printed dental implants

3D-printed dental implants commonly use metals such as titanium and cobalt-chromium alloys, as well as ceramics like zirconia. These dental implant materials offer excellent biocompatibility, strength, and the ability to integrate with the jawbone. Here are most common materials in 3D printed dental implant

1. Metals:

- Titanium:

3D Printed titanium dental implants are made from titanium alloys using advanced 3D printing technology. Titanium dental implant remains the gold standard in dental implants, offering excellent strength, durability, and biocompatibility.

- Cobalt-chromium:

Cobalt-chromium alloys are known for their superior mechanical strength and corrosion resistance. While less common than titanium, they are sometimes used in implant frameworks, especially where high strength and wear resistance are required.

2. Ceramic and composite:

- Zirconium (Zirconia)

3D-printed zirconia crowns are highly biocompatible and known for their strength, durability, and natural appearance. Zirconia implants provide excellent aesthetic qualities, including color and contour, making them a reliable option for matching natural teeth.

- Resin-Based Composite

3D-printed resin composite crowns can be customized to achieve proper strength and a natural appearance. However, they are generally less durable and of lower quality compared to zirconia crowns, but they remain a more affordable option. They are commonly used for temporary or short- to medium-term restorations.

Discover the Top Dental Implant Brands in Turkey 2025 & How to Choose

The Importance of Biocompatibility for a 3D-Printed Dental Implant

The Importance of Biocompatibility for a 3D-Printed Dental Implant

Biocompatible materials are non-toxic, chemically and physically stable over long periods, and free from irritants, cytotoxicity, or allergy-inducing substances. Biocompatibility is crucial for the success of 3D-printed dental implants, ensuring they integrate well with the surrounding tissues and bone without causing adverse reactions.

3D-printed dental implants utilize a variety of biomaterials, including metals such as titanium and its alloys, ceramics, and polymers. All of these materials share one important feature: biocompatibility with human tissue.

The selection of biomaterials for dental implants depends on aesthetic considerations, durability, and material strength. Other factors include the patient’s age, overall health, lifestyle habits (such as smoking or alcohol consumption), expected longevity of the implant, desired aesthetics (color and shape), and the complexity of the treatment plan.

Steps of the 3D-Printed Dental Implant Procedure

1. Digital Design

The process starts with creating a 3D model of the patient’s teeth and gums using advanced digital scanning. This model helps define the exact size, shape, and surface details of the implant site.

2. Customized Implant Design

With CAD/CAM software, dental specialists customize the implant or artificial tooth to perfectly match the patient’s oral structure. This ensures a precise fit and natural appearance.

3. 3D Printing

The final design is sent to a 3D printer, which builds the implant layer by layer using biocompatible materials such as titanium or ceramic. This step allows for high precision and durability.

4. Post-Processing

After printing, the implant goes through finishing procedures like polishing, heat treatment, or chemical processing to achieve the final shape, strength, and smoothness.

3D Printed Dental Implants Limitations

1.3D printing is still not appropriate for the implant itself, Screws and main implant bodies are still mostly produced using conventional methods.

2. 3D-printed materials must meet strict clinical standards for strength and fatigue resistance, which can limit the range of usable materials.

3. Additionally, regulatory challenges make it difficult for many clinics to adopt 3D-printed implant components.

Future of 3D-Printed Dental Implants in Turkey

With the world increasingly shifting toward digitalization as a precise tool to enhance cost-effectiveness, procedural success, and patient comfort, a promising future for 3D-printed implants is expected. Ongoing research aims to expand the use of this technology for implant fabrication, potentially enabling fully 3D-printed implants and widespread adoption as a common method for tooth restoration.

3D Printed Dental Implant vs. Traditional Implant

| Feature | 3D-Printed Implants | Conventional Implants |

| Customization | High – tailored to patient’s anatomy for better fit, function, and aesthetics | Low – standardized designs, may not perfectly match patient anatomy |

| Precision | High – intricate designs and internal structures possible, enhancing osseointegration | Standard – limited to conventional manufacturing capabilities |

| Turnaround Time | Faster – digital workflow and 3D printing can shorten fabrication and treatment time | Standard – may take longer due to traditional fabrication and fitting |

| Material Waste | Reduced – digital workflow minimizes excess material | Moderate – conventional machining can produce more waste |

| Complex Geometries | Possible – internal lattices and detailed designs to improve implant performance | Limited – conventional methods cannot produce highly complex internal structures |

| Cost | Higher – especially for small production runs or highly customized implants | Lower – generally more affordable, especially for routine procedures |

| Material Options | Limited – fewer 3D-printable materials compared to conventional implants | Broad – established and well-studied materials like titanium and zirconia |

| Post-Processing | Often required – may add time and cost | Usually minimal – ready-to-use implants from manufacturer |

| Availability | Limited – depends on location and technology access | High – widely available from multiple manufacturers |

| Clinical Track Record | Emerging – promising results but less long-term data | Established – decades of successful clinical use |

| Procedure Invasiveness | Potentially less – precise fit may reduce drilling and bone preparation | Potentially more – may require additional bone preparation or adjustments |

Get a Precise 3D Dental Implant with Turkey Luxury Clinics

The incorporation of 3D printing technology in dental implants represents a pivotal advancement in the field of dentistry. 3D printing is set to transform dental care with its ability to produce highly customized, precise, and cost-effective implants, offering improved outcomes and greater accessibility.

For those seeking affordable 3D-printed dental implants in Turkey, this also presents an excellent opportunity for dental tourism in Turkey, combining high-quality treatment with a memorable travel experience. Contact Turkey Luxury Clinics today for a personalized consultation and tailored treatment plan.

.webp)

.webp)

.webp)

.webp)